Hungary, 1121 Budapest, Konkoly-Thege Miklós út 29-33 +36.1.392.2642 +36.1.392.2282 1991–2026 Mirrotron Ltd.

Neutron Detectors

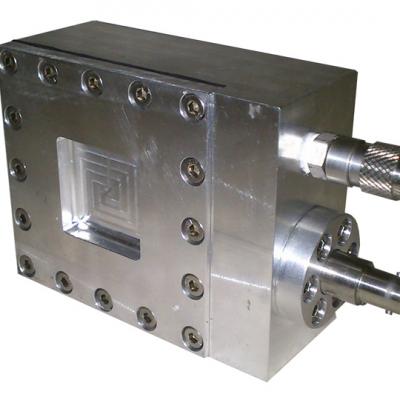

Position Sensitive 2D Detectors

- for regular in-situ NG diagnostic

- cross-section neutron intensity distribution (TOF application-the diagnostic is wavelength dependent)

- Custom designed based on active area and spatial resolution requirements

- Position encoding technique: delay line

- Anode and cathode wires: Gold-Tungsten

- Filling gas: Helium-3 and CF4

- Dynamic range: single neutron detection

- 5 preamplifiers built in

- Commercial CFD and TDC can be connected or vendor-supplied

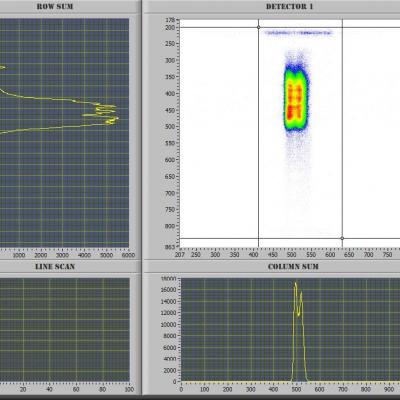

- XY projection, integration; open interfaces for easy integration to existing software

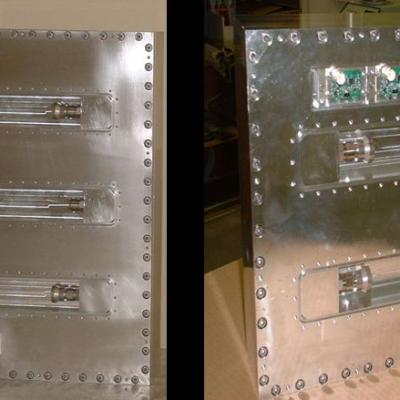

Test "Black" Detector

- for efficiency test

- flux measurement (TOF application-the diagnostic is wavelength dependent)

- advantage to tube: high count-rate capability, planar arrangement: constant active gas depth

- Model No. MWBD-30

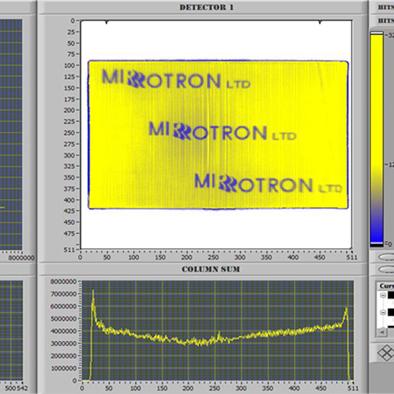

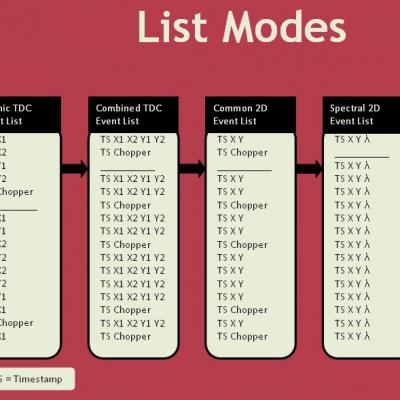

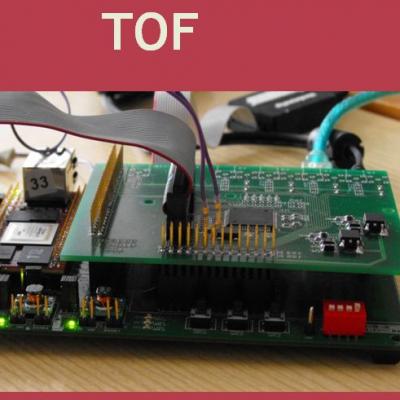

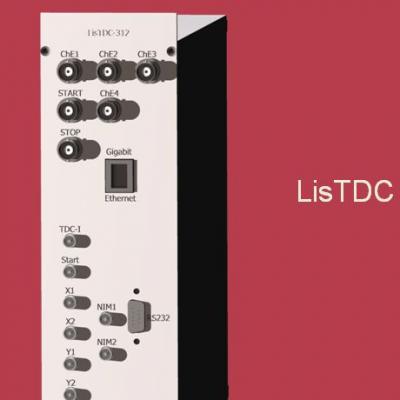

PSD Data Acquisition Unit

- Model No. LisTDC-312

- With ACAM chip/a (serial/parallel)

- With ACAM chip/b (Time Stamp)

- Only FPGA (Isherd)

- Measurement of a number of parallel events

- Data gathering

- Series of filters

- Filtering: e.g. by wavelength intervals

- Histogram generation

- Events are recorded in lists

- Lists are processed into histograms

- Lists remain available for revisiting

- Common 2D Event List

- Spectral 2D Event List

- 2D information (X & Y) extracted from Stop signals

Beam Monitors

- Custom designed and optimized to beam size

- Total thickness: ~ 20 - 22 mm

- Window thickness: 0.5 mm

- Anode wires: Gold-Tungsten

- Filling gas: Nitrogen or Helium-3, Helium-4 and CF4

- Optionally, built-in SHV BNC

- Calibrated and certified by neutrons

- Re-charge/re-calibration option

- Visualization counter software with open interfaces for easy integration to existing software

- BME - Beam Monitor Electronics - AMP / SCA / HV

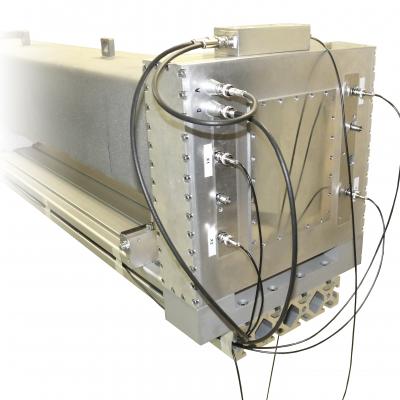

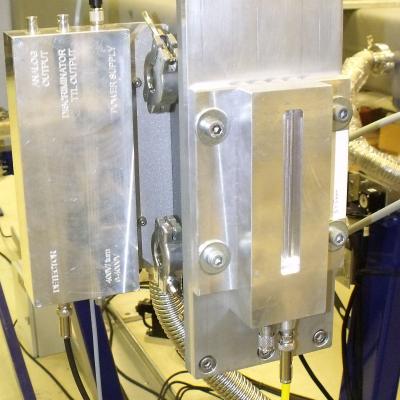

Position Sensitive Neutron Beam Monitor

- Overall dimensions: 270 x 190 x 45 mm3

- Active area: 200 x 65 mm2

- Window thickness: 0.5 mm - 2 mm (on gas pressure)

- Gas filling: 3He at ultra low pressure or N2 +CF4+ 4He

- Position resolution: 1.8 x 1.8 mm2 (FWHM)

- Gas connector: Swagelok QC series

- Detection efficiency: 10-5 to 10-3 ( 0.025eV/1.8Å).

Integrated Monitor Control Unit

- Model No. LisMon-331

- Standard functionality Monitor (Inhibit)

- List Mode Monitor (Start/Stop)

- Advanced List Mode (Monitor Count in List)